Iyo conveyor system inotakura nekutakura zvinhu, kazhinji munzvimbo yeindasitiri kana inodzorwa.Conveyor mabhandi ndeye yakaedzwa-uye-yechokwadi simba saver yakagadzirirwa kuwedzera kushanda zvakanaka.Ngatitarisei kuti mabhandi ekutakurisa anoshanda sei uye nei akamira kwenguva yakareba.

Mashandiro Ebhandi reConveyor?

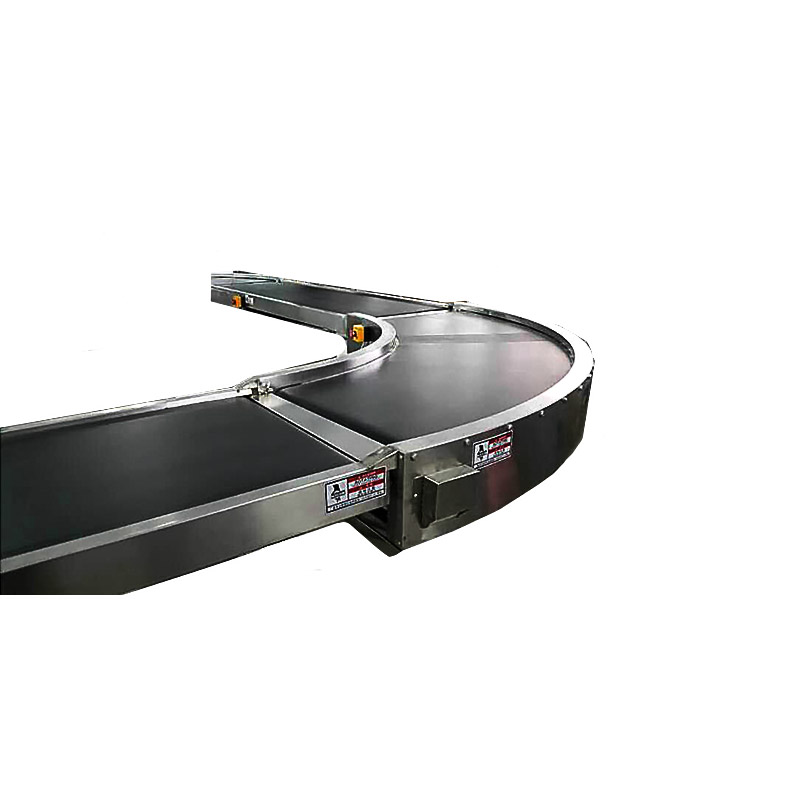

Bhandi rekutakura rinoshanda nekushandisa mapulley maviri ane mota anomonereka pamusoro pezvinhu zvakakora uye zvinosimba.Kana mamotor ari mumapulleys anoshanda nekumhanya kwakafanana uye achitenderera munzira imwechete, bhandi rinofamba pakati pezviviri.

Kana zvinhu zvakanyanya kurema kana kurema - kana kana iyoconveyor beltari kuvatakura kwechinhambwe chakareba kana nguva - rollers inogona kuiswa pamativi ebhandi rekutakura kuti ritsigire.

Zvikamu zveConveyor Belt System

Kunyange paine akawanda marudzi emaconveyor system, ese anoshanda chinangwa chakafanana chekutakura zvinhu.Zvimwe zvigadzirwa zvingada hurongwa husina bhandi, uchishandisa chete rollers kana mavhiri ekufamba-famba.Nekudaro, akawanda maconveyor masisitimu anovimba nefuremu ine bhandi uye inogoneka yekutsigira rollers kutakura zvinhu uye zvigadzirwa nemazvo.

Yese maconveyor masisitimu ane zvinhu zvitatu zvakakosha - iyo aluminium profiles, yekutyaira unit uye yekupedzisira unit.

Mune inotakura bhandi system, iyo aluminium mbiri ine furemu, bhandi uye chero zvitsigiro.Masisitimu anoshandisa bhandi anowanzo kufambiswa nemota, kunyangwe maconveyor masisitimu anogona zvakare kushandisa giravhiti kana simba remanyorero kushanda.Mabhandi ekutakurisa mota akanakira kushandiswa kwemaindasitiri sezvo achinyanya kuvimbika uye anoshanda - dhiraivha yemasisitimu akadaro inosanganisira bhuroketi remota, dhiraivha yemagetsi uye chero mabhengi ekupikisa.

Iyo conveyor belt system's extremity unit inowanzo sanganisira chero pulley uye clamping tambo.Zvimwe zvimire kana lateral madhairekitori anogona kudiwa kune chaiwo misiyano kana mabasa, saka funga nezvezvinodiwa zveindasitiri yako paunosarudza izvi zvekuwedzera zvekuwedzera.Zvikamu uye mabasa eiyo itsva conveyor belt system inogona kusanganisira:

● Chimiro: Chimiro chegadziriro inobata zvikamu zvose zvinofamba pamwe chete kuitira kushanda kwakachengeteka uye kwakachengeteka.

● Bhandi: Rakareba rechinhu chakakora, chakasimba chinotakurwa zvinhu kubva pane imwe nzvimbo kuenda kune imwe.

● Rutsigiro rwebhandi rekutakura: Marollers anobatsira bhandi kuti rirambe riri munzira uye nekukurumidza kuchengetedza kufamba.Ma rollers anochengeta zvinhu munzvimbo uye anodzivirira bhandi kubva pakudonha.

● Chikwata chekutyaira: Mota dzingashandisa magiya anochinja-chinja kana kuti anogara achideredza kumhanya kuti aise magetsiconveyor belt.Iyo inonyatso dhiraivha unit inofanirwa kugara ichibatsira bhandi nekuenderera mberi ichimhanya, inotsvedzerera kumashure uye ichidzokorodza kudzokorora nzira.

● Madhiri: Bhandi rinotakura zvinhu rinofanira kumonereka pamusoro pemapuleti maviri kana anopfuura akaiswa zvine unyanzvi.Iyo pulley inodzora kufamba kwebhandi uye inoita mabasa akakosha akadai sekutyaira, kutungamira, kutendeuka, kumanikidza uye kuronda bhandi.

● Mabhandi ekusunga: Mabhandi ekusungisa anoshandiswa pamichina yakasiyana-siyana kubata pasi zvinhu uye zvinoriumba.

● Wedzera-pamamodules: Zvizhinji zvekuwedzera zvikamu zvakaiswa kuti zviwedzere kusimbiswa.Kunyange zvazvo ma rollers achitsigira bhanhire kubva mukati megadziriro, anomira uye madhairekitori emashure anotsigira chimiro chekunze.

Conveyor bhandi inogona kugadzirwa kubva kwakasiyana zvinhu, zvinosanganisira rabha, simbi, dehwe, machira nepurasitiki.Funga nezvemamiriro ayo sisitimu yako ichashanda pasi payo kuti ive nechokwadi chekuti conveyor bhandi zvinhu ndezveukobvu uye kusimba kwakakodzera.

Nguva yekutumira: Mar-07-2023